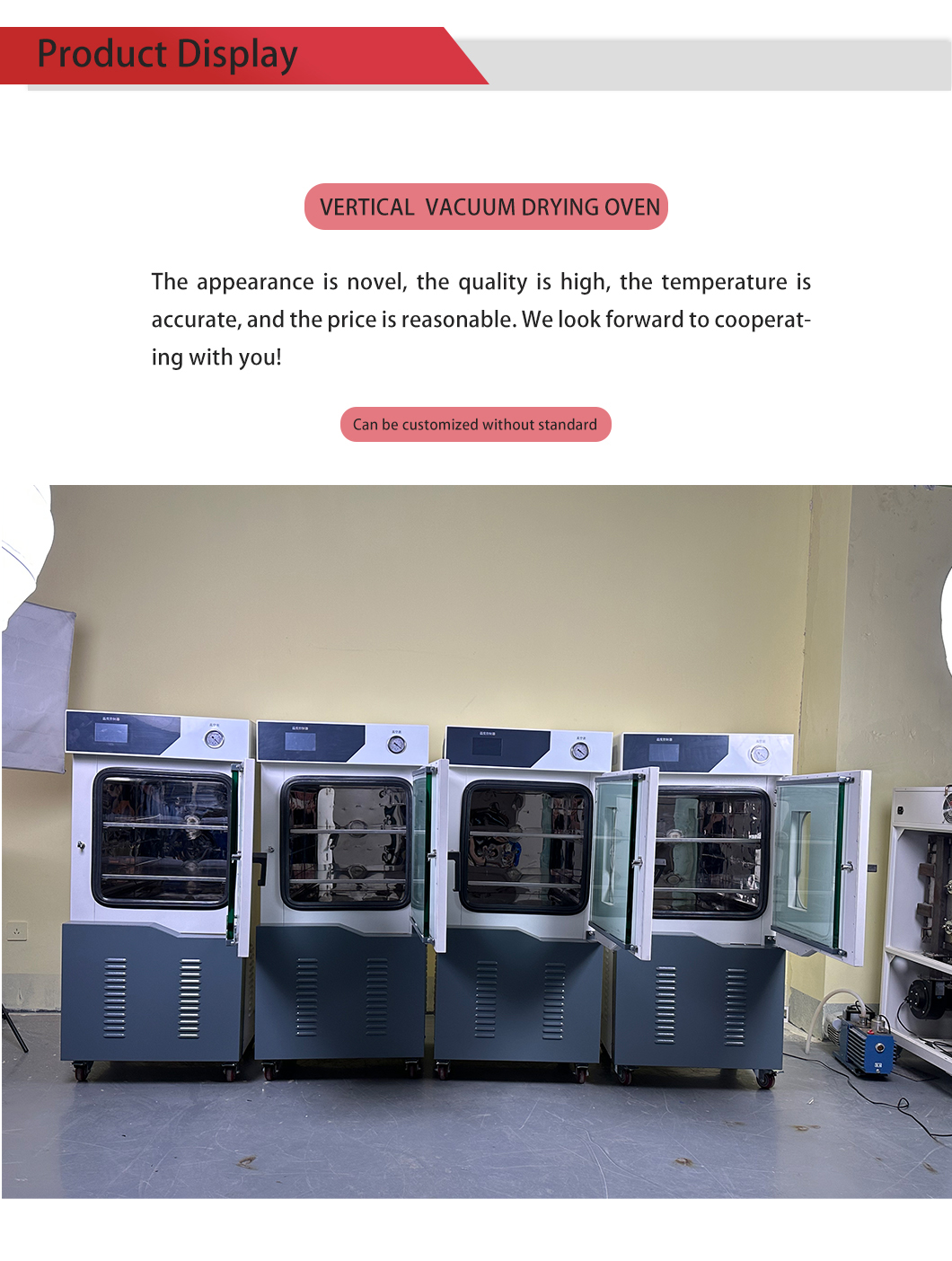

Factory Price 24L 50L 250L LCD Screen Laboratory Vacuum Oven Vacuum Drying Oven

Specifically designed for degassing items such as glue and silica gel, preventing cosmetics from leaking, and drying heat-sensitive, easily decomposable and oxidizable substances. It can fill inert gases inside, and can quickly dry even some items with complex compositions.

Product Details

The vacuum drying oven, also known as a vacuum oven, incorporates the company's years of successful experience in box heating. Through continuous painstaking research, it has creatively overcome the "bottleneck" in the heat conduction process - finding a perfect heat conduction method.

The vacuum drying oven is specifically designed for drying heat-sensitive, easily decomposable, and easily oxidizable substances. It can be filled with inert gases, and it can even rapidly dry some items with complex compositions.

2. Instrument selling points:

1. The inner tank is made of mirror stainless steel.

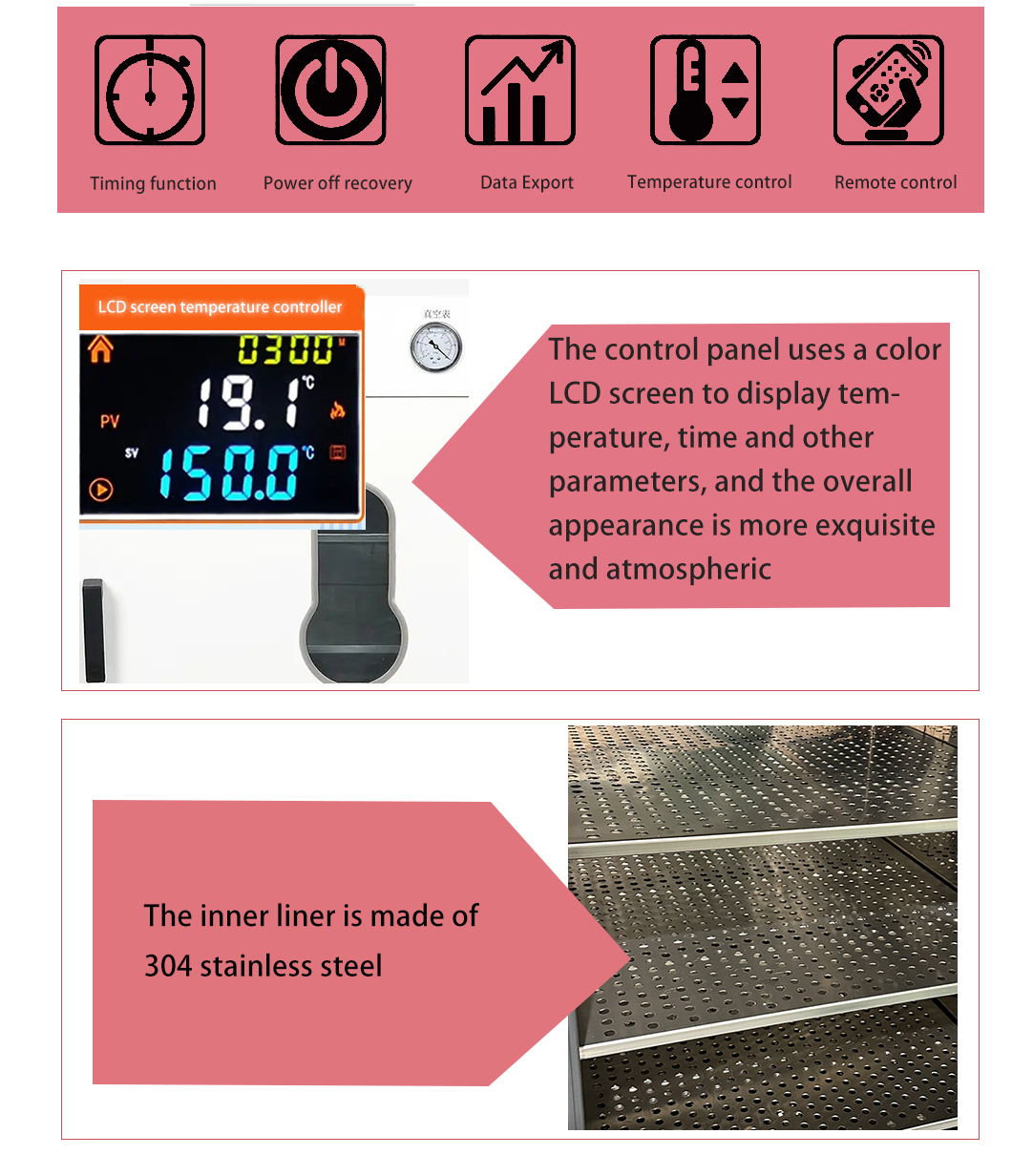

2. Intelligent controller with good temperature control effect.

3. Digital one - screen display for parameters such as temperature and time.

4. Manufactured by an honest enterprise, the product is durable and all parameters are presented without reservation.

5. After - sales service is guaranteed, and there are after - sales services all over the country.

6. Video teaching is provided to reduce the time users spend reading the instruction manual.

3. Unique advantages of the product:

Partition upgrade: (The partition is made of stainless steel steel plate punched, which can solve the unevenness of the grid when placing items in the past)

Left side of the controller: (The controller is on the left side, which is convenient for operation)

Improved air duct structure: (Redesigned strong convection air duct to significantly improve uniformity)

Door handle upgrade: (Upgradeable door handle, simple, light and durable opening and closing door)

Partition upgrade: (First use a number of partition strips to weld inside the inner liner, put the partition plate and box drawer-type pulling, the I-type drying box is hook-type not to pull)

Appearance upgrade: (The overall performance of the equipment is improved, and the appearance is upgraded with exquisite and atmospheric.)

Fan speed regulation function: (can adjust the wind speed)

Programmable controller: (Standard equipped with 9999 cycles, 50-segment programming)

4. Humanized design:

The streamlined and luxurious overall machine shape is full of aesthetic design concepts. The box body is electrostatically sprayed, and there is a large - angle tempered glass observation window on the door.

It is made by mirror - finished stainless - steel argon arc welding. The outer box is made of high - quality steel plates, with a beautiful and novel appearance. The mirror - finished stainless - steel inner lining makes the instrument corrosion - resistant.

The LCD color display screen shows various set parameters and measured parameters.

The new - type synthetic silicon sealing strip can operate continuously at high temperatures, has a long service life, and is easy to replace.

The hot - air circulation system is composed of a fan that can operate continuously at high temperatures and a suitable air duct, improving the temperature uniformity in the working chamber.

The loading brackets in the box can be adjusted freely.

5. Introduction to the control system:

Adopt a microcomputer P.I.D temperature controller with over-temperature deviation protection and digital display. It has a timing function, and the temperature control is stable and reliable.

The upgraded microcomputer chip with audible and visual alarm and environmental scanning has a stable data processing function.

Functions such as over-temperature alarm, timed shutdown, power recovery, parameter encryption, and temperature correction are available.

It has a power-off recovery function. After the external power supply suddenly fails and then resumes, the equipment can automatically resume operation according to the original set program.

6. Safety functions:

Considerate safety protection design to achieve triple safety protection for personnel, samples and equipment.

Safety functions: sensor failure alarm, over-temperature alarm, separate overshoot preventer, separate over-temperature protector, over-current trip protection, etc.

7.technical parameter

|

product name |

Vertical vacuum drying chamber |

|||

|

product model |

DZF-6090(90L) |

DZF-6210(210L) |

DZF-6250(250L) |

DZF-6500(500L) |

|

Inner size (D*W*H) mm |

450*450*450 |

580*560*640 |

600*700*600 |

810*630*845 |

|

External Size (D*W*H) mm |

610*630*1370 |

750*730*1560 |

750*880*1520 |

1020*810*1710 |

|

power (W) |

2200W |

3600W |

4800W |

6800W |

|

volume (L) |

90L |

210L |

250L |

500L |

|

supply voltage |

AC220V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

AC380V 50HZ |

|

temperature range |

Room temperature +10~250℃ (commonly recommended below 200℃) |

|||

|

temperature resolution |

0.1℃ |

|||

|

temperature fluctuation |

≤±1℃ |

|||

|

Timing range |

1 to 9999 (minutes/hour switchable) |

|||

|

Carrying frame (block) |

2~4(block) |

|||

|

apolegamy |

Curve heating, printer, RS485, interface, mobile phone remote control and other ancillary options |

|||

|

Net weight (kg) (approx.) |

160kg |

216kg |

246kg |

380kg |

|

Gross weight (kg) (approx.) |

180kg |

236kg |

266kg |

390kg |