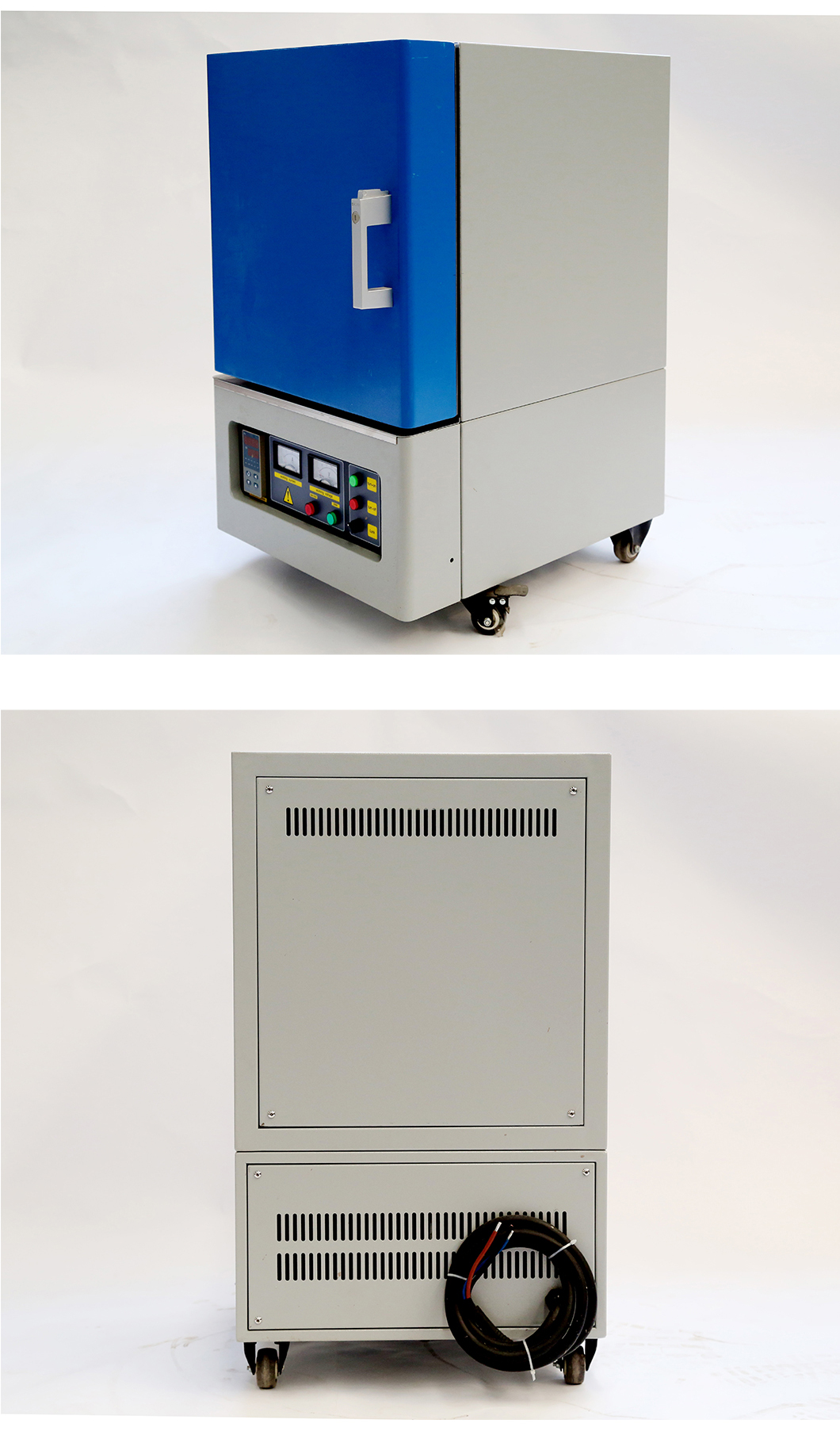

Box type electric heating laboratory muffle furnace

The box-type electric heating laboratory furnace is equipped with high-quality heating elements, a double-shell structure, and an intelligent automatic temperature control system. It supports SCR control and phase triggering. An intelligent cooling system is installed between the two shells. When the surface temperature reaches 50℃, the cooling fan will automatically activate to maintain a low surface temperature. The furnace uses constant current soft start control, which extends the lifespan of the heating elements. It is suitable for powder sintering, ceramic sintering, high-temperature experiments, material handling, and quality inspection in universities, research institutions, and industrial and mining enterprises.

Product Details

Box type electric heating laboratory muffle furnace

■ scope of application

The box-type electric heating laboratory furnace is equipped with high-quality heating elements, a double-shell structure, and an intelligent automatic temperature control system. It supports SCR control and phase triggering. An intelligent cooling system is installed between the two shells. When the surface temperature reaches 50℃, the cooling fan will automatically activate to maintain a low surface temperature. The furnace uses constant current soft start control, which extends the lifespan of the heating elements. It is suitable for powder sintering, ceramic sintering, high-temperature experiments, material handling, and quality inspection in universities, research institutions, and industrial and mining enterprises.

■ functional characteristics

1. The furnace is made of high quality alumina polycrystalline fiber, using Japanese technology (vacuum suction molding alumina polycrystalline fiber)

2. Good thermal insulation and durability, high tensile strength, no impurities, so the furnace is much more energy saving than ordinary fiber materials.

3. The temperature control system adopts artificial intelligence technology and has PID control and self-adjustment function

4. Temperature control accuracy: ±1℃

5. Heating rate: recommended 10℃/min, maximum 30℃/min

6. The side-opening furnace door will automatically cut off the power supply when the furnace door is opened.

7. Three heating surfaces with good thermal field uniformity.

8. Reserve 485 switching interface, which can be connected to PC through software, and has functions such as remote control, real-time tracking, historical records and output reports.

9. High temperature alarm, automatic power off, and leakage protection function to make the operation safer.

■ technical parameter

|

product name |

Box type electric heating laboratory muffle furnace |

||||||||

|

product model |

SX2-1100M |

SX2-1200M |

SX2-1200C |

SX2-1400C |

SX2-1700C |

SX2-1800C |

|||

|

Cavity size (D*W*H) mm |

100*100*100 |

160*150*150 |

300*200*200 |

400*300*300 |

300*200*200 |

400*300*300 |

300*200*200 |

400*300*300 |

400*300*300 |

|

Overall size (D*W*H) mm |

210*210*210 |

280*350*400 |

470*600*700 |

580*700*800 |

470*600*700 |

580*700*800 |

470*600*700 |

580*700*800 |

580*700*800 |

|

power rating |

1KW |

3KW |

4KW |

8KW |

6KW |

8KW |

6KW |

14KW |

15W |

|

volume (L) |

3L |

8L |

12L |

15L |

12L |

15L |

12L |

15L |

15L |

|

heating element |

0Cr27Al7Mo2 Alloy wire |

silicon carbon rod |

silicon Molybdenum rod |

||||||

|

working temperature |

Continuous operating temperature ≤ 1000℃; Maximum temperature: 1050℃ |

Continuous operating temperature ≤ 1100℃; Maximum temperature: 1150℃ |

Continuous operating temperature ≤ 1300℃; Maximum temperature: 1350℃ |

Continuous operating temperature ≤ 1600℃; Maximum temperature: 1650℃ |

Continuous operating temperature ≤ 1700℃; Maximum temperature: 1750℃ |

||||

|

thermocouple |

N pattern |

S mould |

B pattern |

||||||

|

supply voltage |

AC220V 50/60HZ |

AC380V 50/60HZ |

|||||||

|

Bottom fasteners |

Bottom of the foot |

||||||||

|

firepot |

The furnace chamber is made of high quality alumina polycrystalline fiber, scientifically designed, good durability and thermal insulation performance. |

||||||||

|

Maximum heating rate |

≤30℃/min |

||||||||

|

Recommended heating rate |

10℃/min (less than 120 minutes) |

||||||||

|

rate of cooling |

More than 500℃ less than or equal to 10℃/min |

||||||||

|

Temperature control accuracy |

±1℃ |

||||||||

|

Temperature control type) |

The temperature control system uses artificial intelligence technology, with PID control, self-adjustment function, 30 heating and cooling programs |

||||||||

|

standard fitting |

One crucible clamp; one high temperature glove and one warranty card |

||||||||