Vacuum tube laboratory muffle furnace

The vacuum tube electric furnace features a dual-shell design and an intelligent program temperature control system, equipped with phase triggering and SCR control functions. The furnace chamber is made of imported polycrystalline alumina fiber material, and an air cooling system is installed between the two shells to facilitate rapid heating and cooling. Additionally, the lid can be opened for quick cooling. The design is both structurally sound and aesthetically pleasing. It is suitable for high temperature sintering atmosphere, atmosphere reduction, CVD experiment and vacuum annealing in universities, scientific research institutions, industrial and mining enterprises.

Product Details

Vacuum tube laboratory muffle furnace

■ scope of application

The vacuum tube electric furnace features a dual-shell design and an intelligent program temperature control system, equipped with phase triggering and SCR control functions. The furnace chamber is made of imported polycrystalline alumina fiber material, and an air cooling system is installed between the two shells to facilitate rapid heating and cooling. Additionally, the lid can be opened for quick cooling. The design is both structurally sound and aesthetically pleasing.

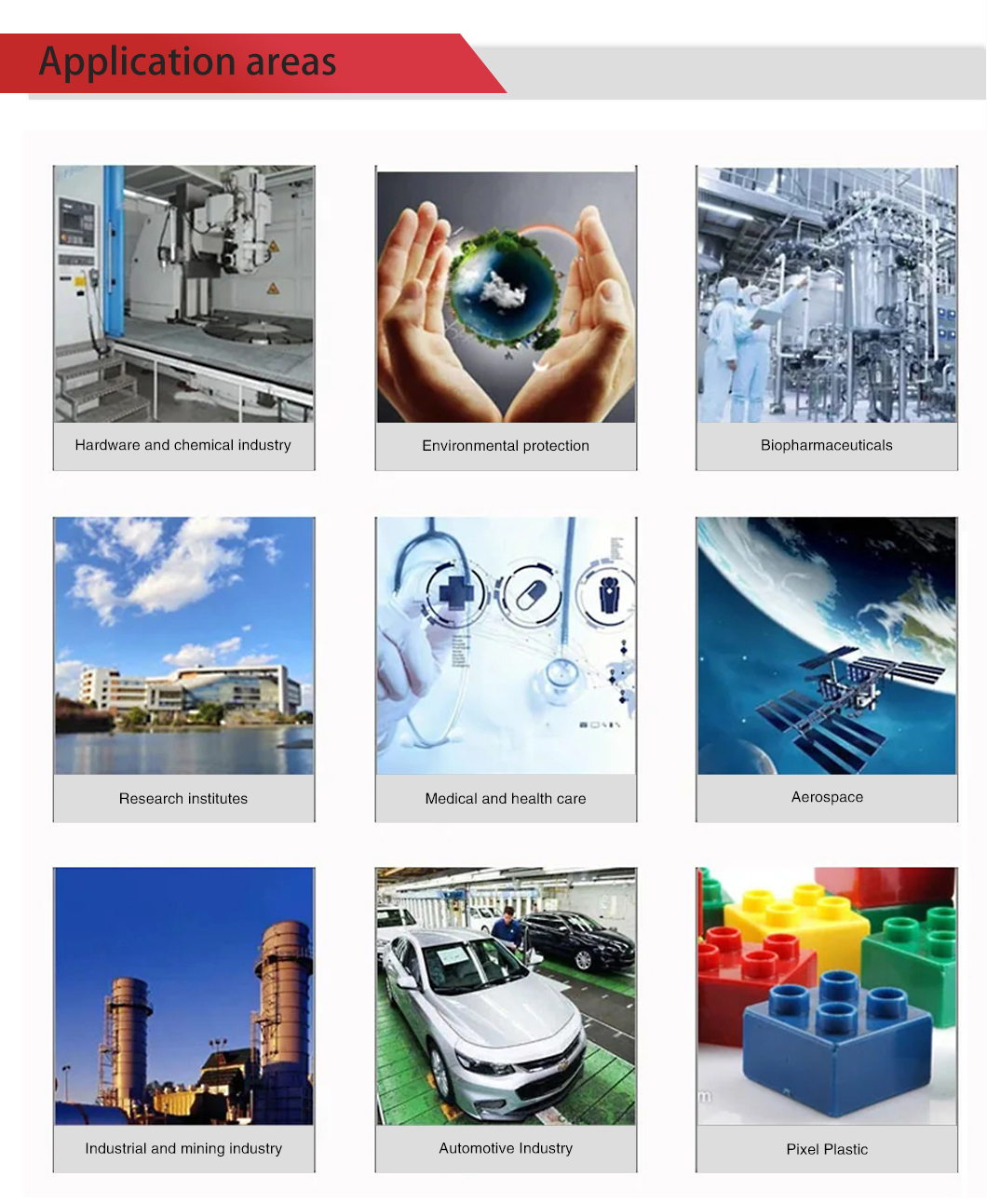

It is suitable for high temperature sintering atmosphere, atmosphere reduction, CVD experiment and vacuum annealing in universities, scientific research institutions, industrial and mining enterprises.

■ functional characteristics

1. Use KF quick flange seal, only one clamping flange can complete the connection, take and place samples very convenient,

It avoids bolt leakage during manual operation and reduces the proportion of heating tube damage caused by flange installation.

2. Use imported polycrystalline fiber vacuum thermoforming furnace chamber

3. Reserve vacuum and gas road quick interface, which can be used with our vacuum system or mixed gas system.

4. The temperature control system adopts artificial intelligence technology and has PID control and self-adjustment function

5. Temperature control accuracy: ±1℃

6. Heating rate: recommended 10℃/min, maximum 30℃/min

5. Built-in thermocouple to monitor the temperature of heating material in real time.

6. Reserve 485 conversion interface, which can be connected to PC through software, with remote control, real-time tracking, and historical records

Output reports and other functions, and can install paperless recorder for data storage and output.

7. When the temperature is too high, alarm and automatically cut off the power supply, and have leakage protection function to make the operation more safe.

■ technical parameter

|

product name |

Vacuum tube laboratory muffle furnace |

||||||

|

product model |

MRT-VTF-1200M |

MRT-VTF-1200C |

MRT-VTF-1200-Ⅱ |

MRT-VTF-1400C |

MRT-VTF-1400-III |

MRT-VTF-1700C |

MRT-VTF-1700-II |

|

caliber (OD*L, mm) |

60/50*600 |

40/60/80 /100*1000 |

Φ40/60/80 /100*1000 |

60/80/100 *1000 |

Ø60/80 *1500 |

60/80/100 *1000 |

Ø40/60/80 *1200 |

|

power rating (KW) |

2 |

3.5 |

4.5 |

5 |

6 |

6 |

6 |

|

heating zone |

1 |

1 |

2 |

1 |

3 |

1 |

2 |

|

Length of heating zone |

270mm |

410mm |

220/220mm |

280mm |

200/200/200mm |

280mm |

280/280mm |

|

constant temperature Length of heating zone |

120mm |

200mm |

100/100mm |

120mm |

80/80/80mm |

120mm |

120/120mm |

|

tubing |

quartz tube |

Alumina tube |

Alumina tube |

||||

|

heating element |

0Cr27Al7Mo2 alloy wire |

silicon carbide rod |

Silicon molybdenum rod |

||||

|

thermocouple |

N pattern |

S pattern |

B pattern |

||||

|

maximum temperature |

1150℃ |

1350℃ |

1650℃ |

||||

|

continuous work temperature |

1000℃ |

1300℃ |

1600℃ |

||||

|

vacuum pump |

Zhejiang Feiyue, Laibao and Edward import brands are available |

||||||

|

remarks |

Customizable development of other working sizes |

||||||