Salt Spray Test Chamber for Neutral and Acidity Salt Spray Test

A fully automatic salt spray test chamber is a device used to simulate a salt spray environment for corrosion testing. It generates salt mist by mixing heated water vapor with a salt solution, mimicking the destructive effects of marine climates on products. This process evaluates the reliability of samples in terms of their resistance to corrosion. Widely applied in material science, automotive manufacturing, electronics, and hardware industries, it assesses the corrosion resistance of materials and products in a salt spray environment. The demand for this equipment grows with the development of manufacturing.

Product Details

Fully automatic salt spray test chamber

FULLY AUTOMATIC SALT SPRAY TEST CHAMBER

■ scope of application

A fully automatic salt spray test chamber is a device used to simulate a salt spray environment for corrosion testing. It generates salt mist by mixing heated water vapor with a salt solution, mimicking the destructive effects of marine climates on products. This process evaluates the reliability of samples in terms of their resistance to corrosion. Widely applied in material science, automotive manufacturing, electronics, and hardware industries, it assesses the corrosion resistance of materials and products in a salt spray environment. The demand for this equipment grows with the development of manufacturing.

■ Product features

1. Low pressure starting solenoid valve: all solenoid valves start at low pressure, and the service life can reach 3 to 4 times that of ordinary solenoid valves.

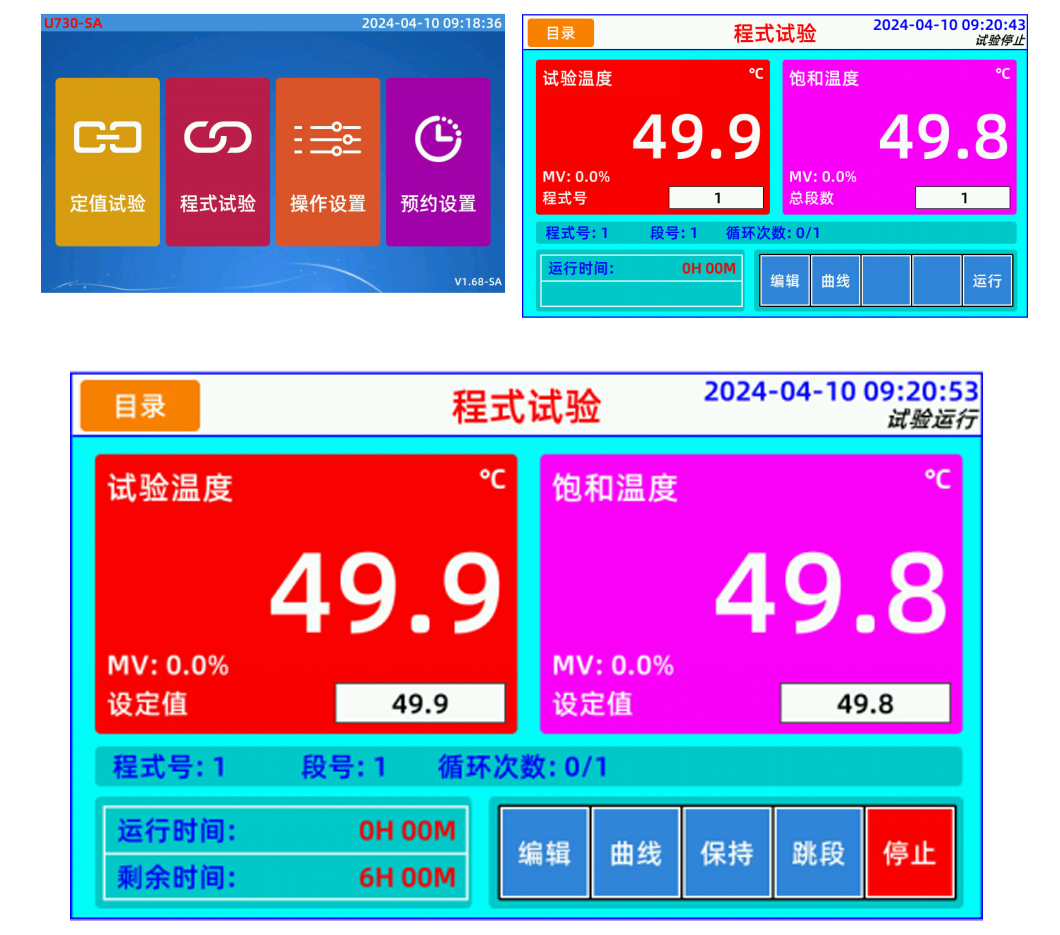

2. Reliable quality touch screen: industrial grade touch screen, easy and sensitive touch, can be touched more than 400,000 times normally.

3. Closed circuit design: the whole closed circuit design makes it impossible for any fine salt spray particles to enter the main circuit box. Compared with the open circuit box of ordinary salt spray box, it has a strong anti-corrosion function. Meanwhile, the service life of the whole machine will be greatly extended.

4. Modular design: The whole machine adopts modular design, and each functional module is mostly plug-in wiring, which not only makes maintenance and overhaul very convenient, but also saves more cost.

5. Water Deficiency Automatic Protection: Automatic low water level protection. When a water deficiency occurs, if a tap water pipe is connected, the corresponding make-up water solenoid valve will automatically open; if the user has not connected a tap water pipe, this salt spray testing machine will enter an automatic standby state (pausing the current test to prevent dry burning of the machine). Once the user manually replenishes the water to the required level, the machine will resume operation.

6. One-click energy saving function: This salt spray test machine has the "one-click energy saving" function. During the test, if the user selects the "one-click energy saving" function, the machine will adjust the output in time according to the situation, and can minimize the waste of energy while ensuring the accuracy of the test, so as to truly achieve energy saving and environmental protection.

7. Setting the "Temperature Zone" to Improve Test Accuracy: This testing machine allows setting the test temperature zone. For example, when conducting a neutral salt spray test according to national standards, the laboratory temperature is set at 35°C, and the pressure chamber temperature is set at 47°C. If we set the "Temperature Zone" to 2℃ in user settings, then only when the laboratory temperature stabilizes between 33℃ and 37℃ will this test proceed

8. Test Type Settings: This salt spray testing machine can perform common NSS (Neutral Salt Spray), AASS (Acidic Salt Spray), and CASS (Copper Accelerated Salt Spray) tests. Each test is pre-set in the "Test Settings" on the main interface, allowing users to select any one of them for testing. The corresponding test type interface provides a brief introduction to the current test solution ratio and relevant precautions. Temperature values and test times are also set by default, but users can modify these settings, including deciding whether to conduct continuous or cyclic tests.

n technical parameter

|

product name |

Fully automatic salt spray test chamber |

|||||||

|

product model |

MRT-YWX-60C |

MRT-YWX-90C |

MRT-YWX-110C |

MRT-YWX-120C |

MRT-YWX-130C |

MRT-YWX-160C |

MRT-YWX-200C |

|

|

Inner tank size (D*W*H) mm |

600*450*400 |

900*600*500 |

1100*750*500 |

1200*800*500 |

1300*800*600 |

1600*900*600 |

2000*1000*600 |

|

|

External dimensions (D*W*H) mm |

1100*750*930 |

1500*900*1150 |

1700*1050*1150 |

1800*1100*1200 |

1900*1100*1300 |

2300*1300*1300 |

2700*1400*1500 |

|

|

uniphase |

2KW 、50HZ. |

2KW 、50HZ. |

3.5KW 、50HZ. |

3.5KW 、50HZ. |

4KW 、50HZ. |

5KW 、50HZ. |

5KW 、50HZ. |

|

|

source |

220V |

220V |

220V |

220V |

220V |

380V |

380V |

|

|

salt spray test |

NSS 、 AASS。 |

|||||||

|

Laboratory temperature |

35℃±1℃. (The set value should not be lower than the ambient temperature at that time) |

|||||||

|

Pressure air tank |

47℃±1℃。 |

|||||||

|

Saline temperature |

Preheat at laboratory temperature |

|||||||

|

temperature uniformity |

≤±2℃ |

|||||||

|

temperature fluctuation |

≤±1℃ |

|||||||

|

proving time |

0-999 hours adjustable |

|||||||

|

amount of precipitation |

1-2ml/80cm2/h |

|||||||

|

Spray method |

NSS (neutral), AASS (acidic), CASS (copper accelerated) test, custom test Verification, programmable test, each test can be independently selected continuous spray or intermittent spray (according to the industry standard standard) |

|||||||

|

specimen holder |

At an Angle of 15 to 30 degrees to the vertical (in the case of standard samples). Other irregular samples are built The pendulum remains tilted. |

|||||||

|

Outer box |

5mm A grade bright PP board (imported from Taiwan) |

|||||||

|

tank cover |

5mm wear-resistant transparent PVC observation window (imported from Taiwan) |

|||||||

|

sample holder |

Grade A PP stent (imported from Taiwan) |

|||||||

|

time relay |

OMRON |

|||||||

|

spray nozzle |

Imports from Taiwan |

|||||||

|

EJO |

Source: China |

|||||||

|

Level switch |

Source: China |

|||||||

|

heating tube |

Pure titanium heating tube |

|||||||

|

auxiliary relay |

Sinohydro CILN China |

|||||||

|

solid state relay |

Kayzer |

|||||||

|

electromagnetic valve |

Yadeke |

|||||||

|

pressure gage |

KK |

|||||||

|

controller |

Xiamen Yudian |

|||||||

|

calculagraph |

OMRON |

|||||||

|

sensor |

Taiwan's divine eyelashes |

|||||||

|

pneumatic system |

Baofeng pneumatic |

|||||||