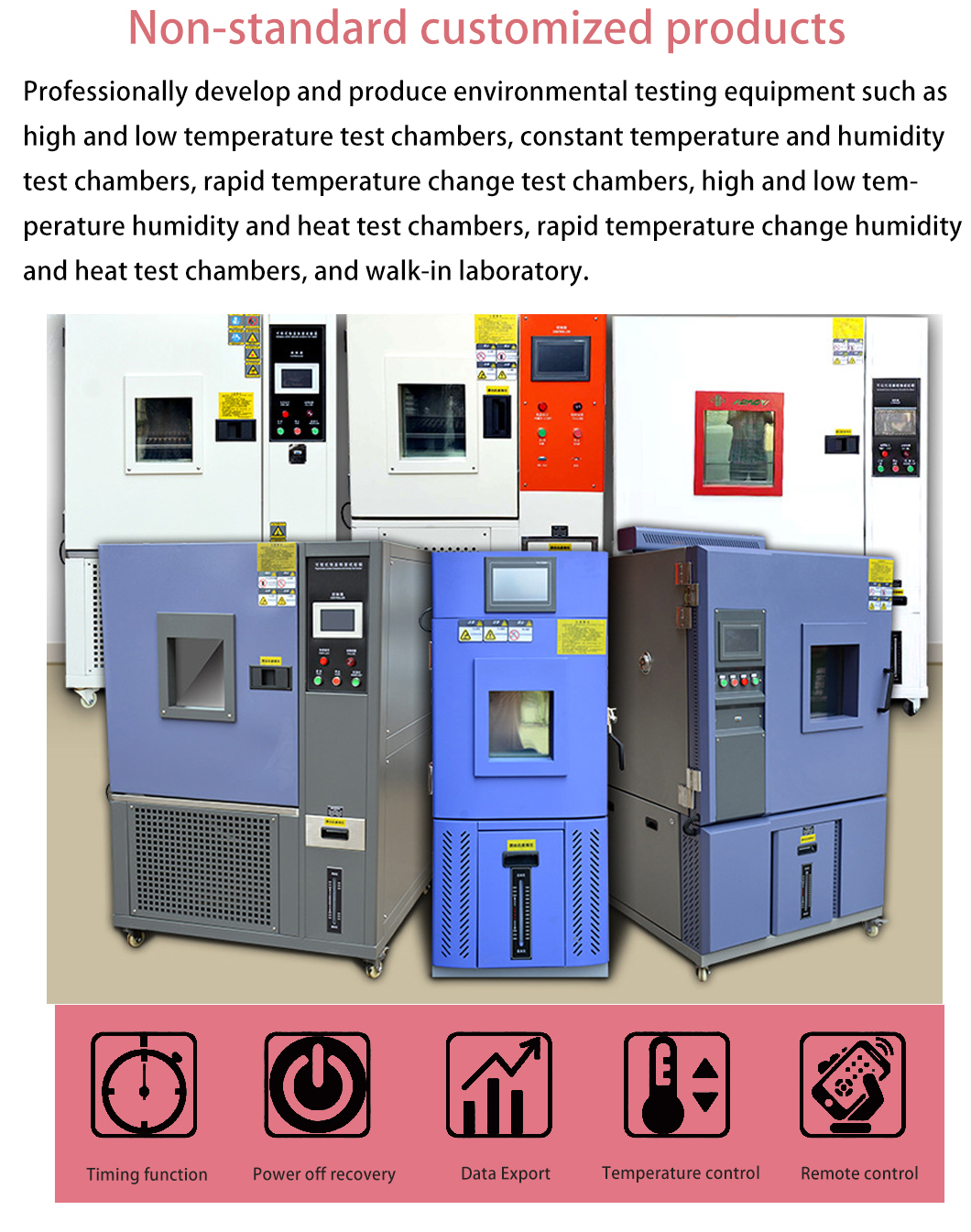

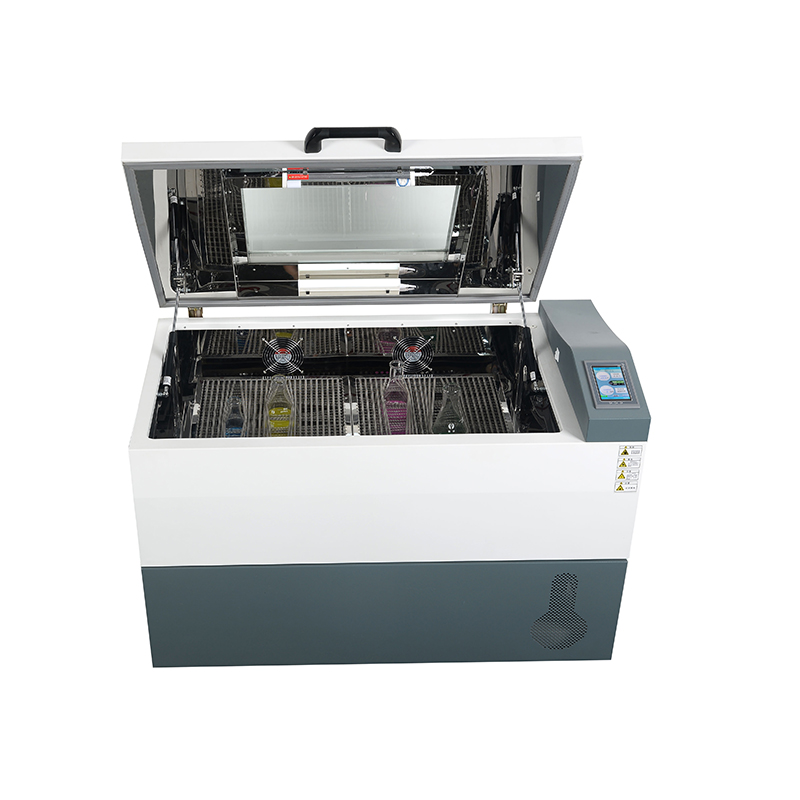

Horizontal Constant Temperature Shaker Machine Laboratory Equipment

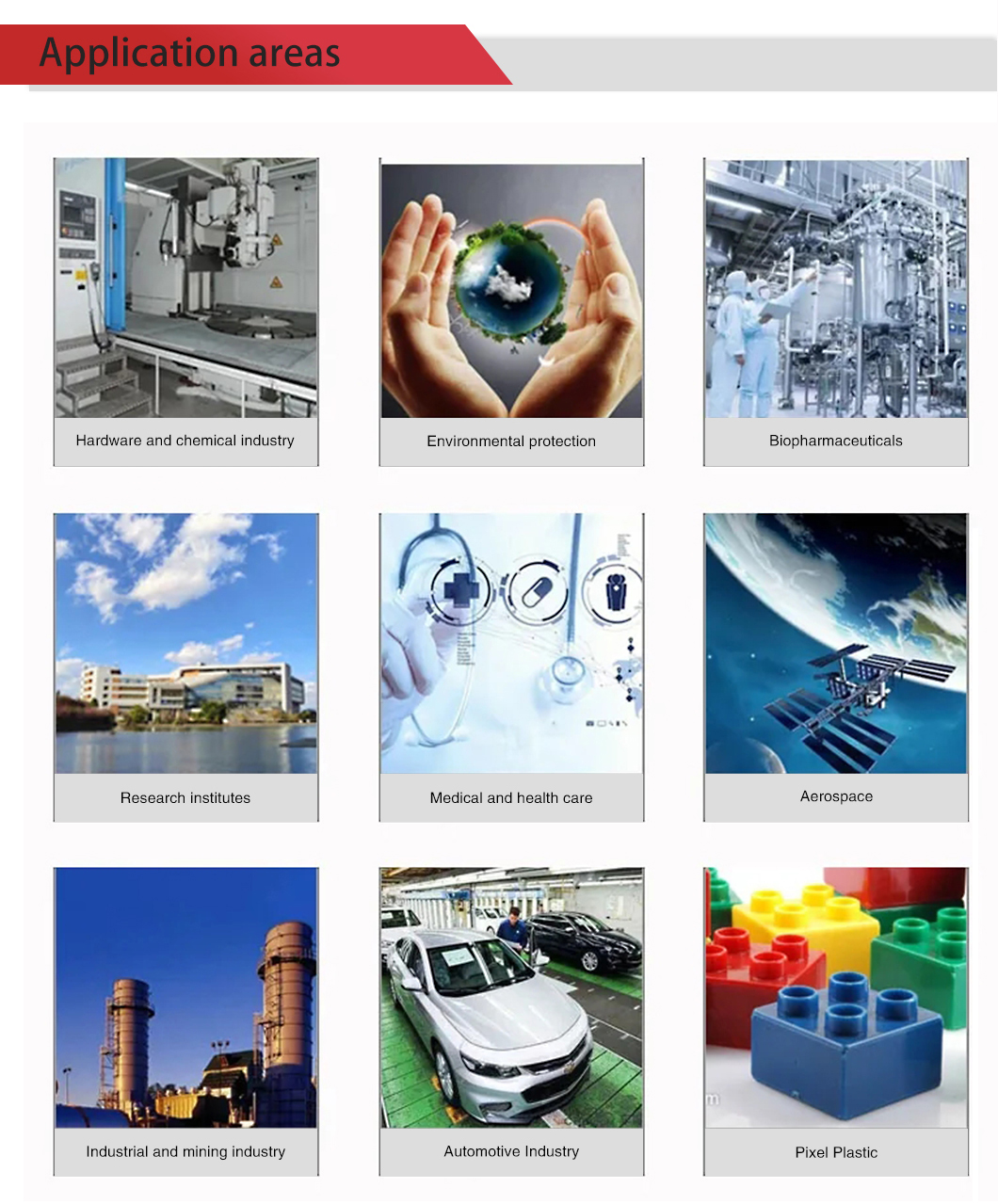

The horizontal constant temperature shaker is widely used for bacterial culture, fermentation, hybridization and biochemical reactions, as well as enzyme and cell tissue research with high requirements for temperature and oscillation frequency. It has extensive and important applications in medical, biological, molecular, pharmaceutical, food, environmental protection and other research and application fields.

Product Details

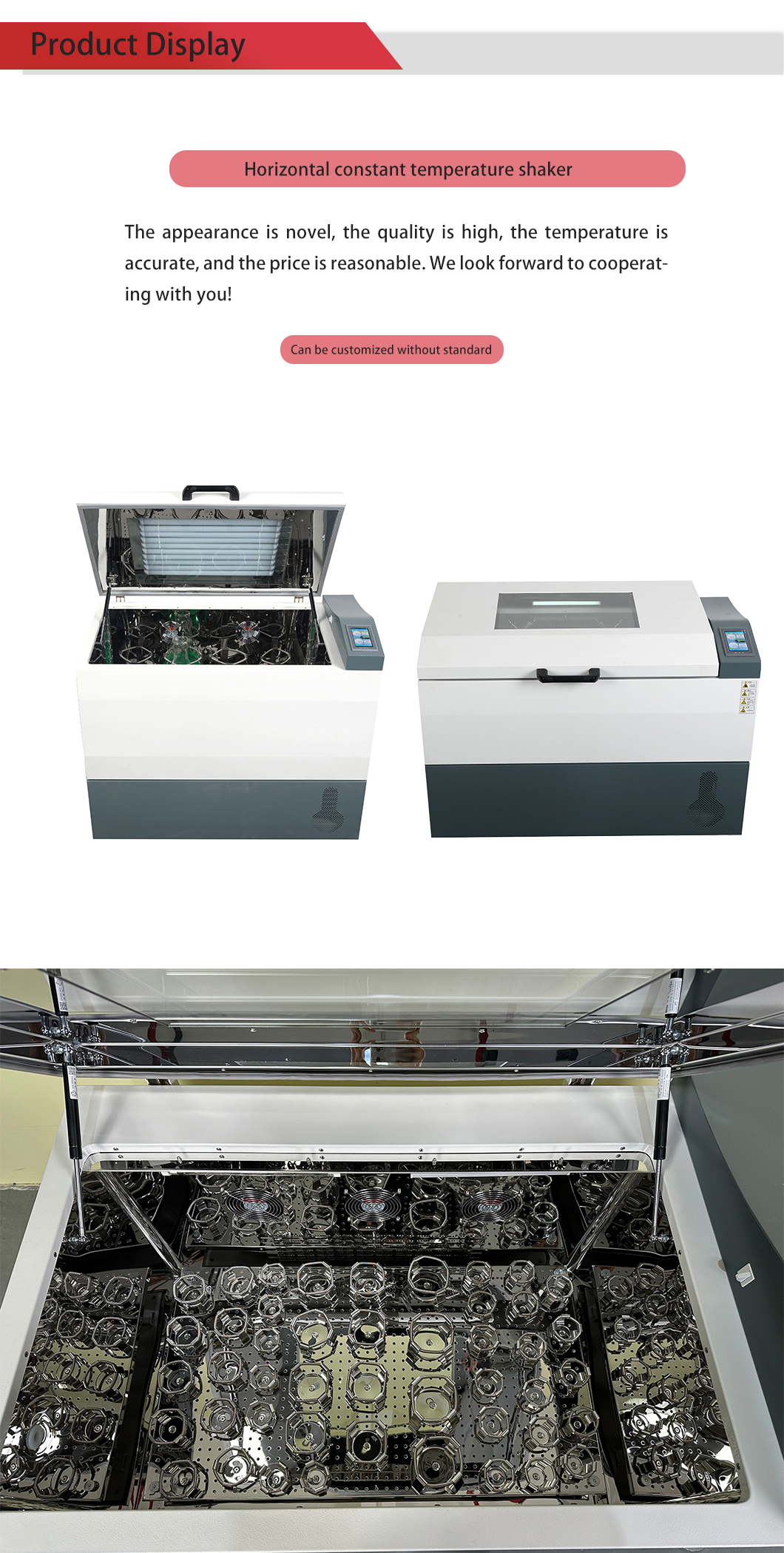

Horizontal constant temperature shaker

■ scope of application

The horizontal constant temperature shaker is widely used for bacterial culture, fermentation, hybridization and biochemical reactions, as well as enzyme and cell tissue research with high requirements for temperature and oscillation frequency. It has extensive and important applications in medical, biological, molecular, pharmaceutical, food, environmental protection and other research and application fields.

■ Product features

1. Personalized program design, up to ten segments of programmable program can be preset, to achieve pre-arranged timing operation of temperature, speed and time

2. It integrates constant temperature incubator and oscillator, saves space, occupies less space, has more functions and less investment.

3. Inclined and humanized control panel, 5-inch HD display screen, better visual effect.

4. It has the function of memory of operating parameters, avoids complicated operation and password lock, and eliminates human error.

5. The call recovery function is provided, which is not affected by the power interruption, and the equipment can automatically resume operation according to the original set program

6. DC motor does not need maintenance for long-term continuous operation

7. The whole machine is designed to be silent, the electrostatic spraying box body, the tempered glass super large view window, and the shape is luxurious and beautiful

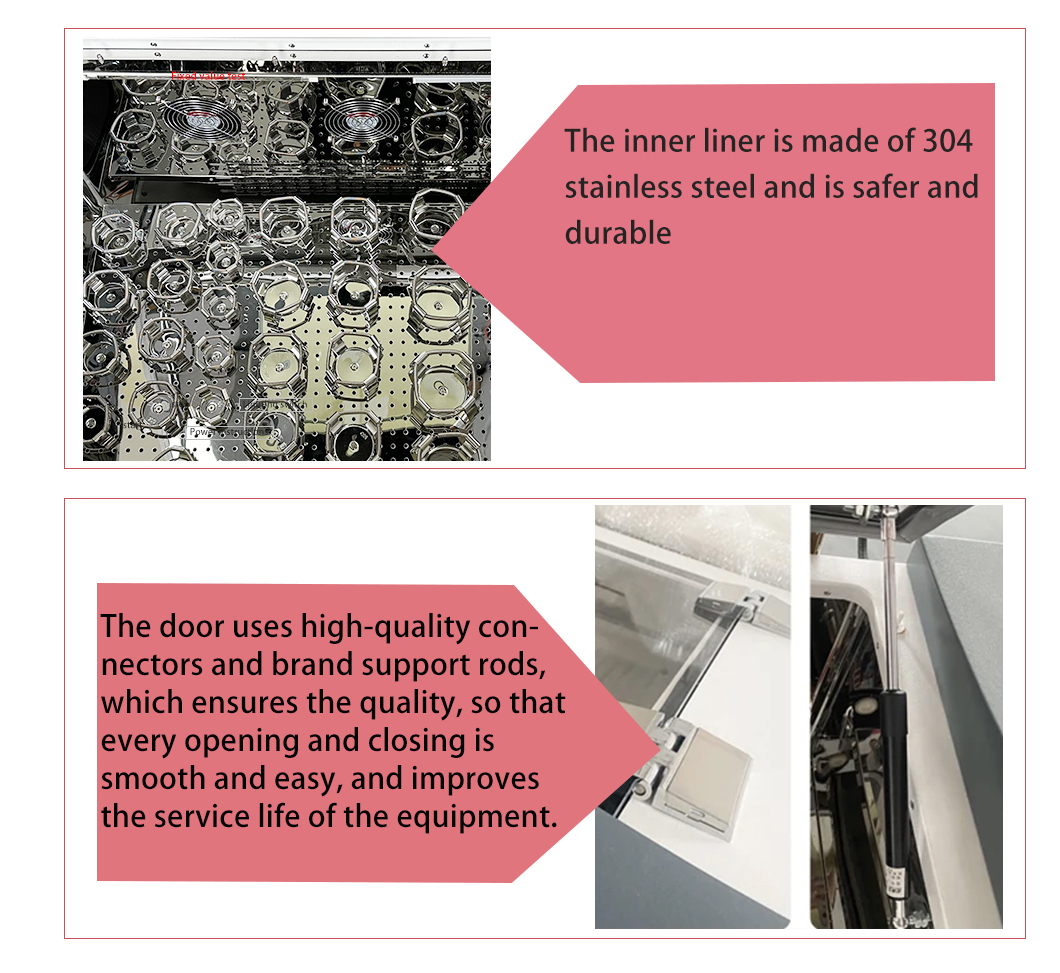

8. Comprehensive safety protection design is considered to achieve triple safety protection for personnel, samples and equipment

9. Parameter memory, temperature representation correction, speed correction

10. AC induction long life motor design, wide speed control, constant torque, constant speed, no carbon brush, maintenance free

11. Mirror stainless steel lining, stainless steel electro-polished tray, spring, flask clamp

12. Flexible and convenient, a variety of detachable tray selection accessories

13. Standardized wechat mini program to realize real-time monitoring and real-time alarm of equipment failure.

■ technical parameter

|

product name |

Horizontal constant temperature shaker |

|

||||||

|

product model |

TS-211B (cooling type) |

TS-111B |

TS-211C (cooling type) |

TS-111C |

TS-211CF (cooling type) |

TS-111CF |

||

|

The shaking method |

The rotary type |

Back and forth + circular |

||||||

|

heating power |

866W |

570W |

951W |

951W |

676W |

676W |

||

|

volume |

168L |

168L |

280L |

280L |

280L |

280L |

||

|

max. cap |

250ml*36 or 500ml*28 or 1000mL*18 |

250ml*36 or 500ml*28 or 1000mL*18 |

1L*18 or 2L*12 or 3L*8 or 5L*6 |

1L*18 or 2L*12 or 3L*8 or 5L*6 |

1L*18 or 2L*12 or 3L*8 or 5L*6 |

1L*18 or 2L*12 or 3L*8 or 5L*6 |

||

|

Inner tank size W.D.H |

980*570*300mm |

980*570*300mm |

980*570*500mm |

980*570*500mm |

980*570*500mm |

980*570*500mm |

||

|

Size W.D.H |

1200*740*800mm |

1200*740*800mm |

1200*740*1000mm |

1200*740*1000mm |

1200*810*1000mm |

1200*810*1000mm |

||

|

standard layout |

500ml*28 tubes |

2000ml*12 bottles |

||||||

|

gyro-frequency |

30~300rpm |

|||||||

|

source |

AC220V~240V 50HZ~60HZ |

|||||||

|

Vibration accuracy |

±1rpm |

|||||||

|

Set the range of the array |

Φ26mm |

|||||||

|

temperature resolution |

0.1℃ |

|||||||

|

fluctuation |

±0.1℃ |

|||||||

|

lighting system |

Built-in lighting, UV sterilization lamp |

|||||||

|

Pallet size |

920*510mm |

|||||||

|

Timing range |

0~9999 hours (minutes/hour can be switched) |

|||||||

|

Temperature control range |

Room temperature +5~60℃ |

|||||||

|

operating ambient temperature |

5℃~40℃ |

|||||||

|

temperature fluctuation |

±0.5℃ |

|||||||

|

display mode |

Touch screen display |

|||||||

|

Number of pallets |

1 block |

|||||||

|

net weight |

174KG |

160KG |

183KG |

183KG |

168KG |

168KG |

||

|

apolegamy |

Printers, RS485 interface, mobile phone remote control and other ancillary functions are optional |

|||||||