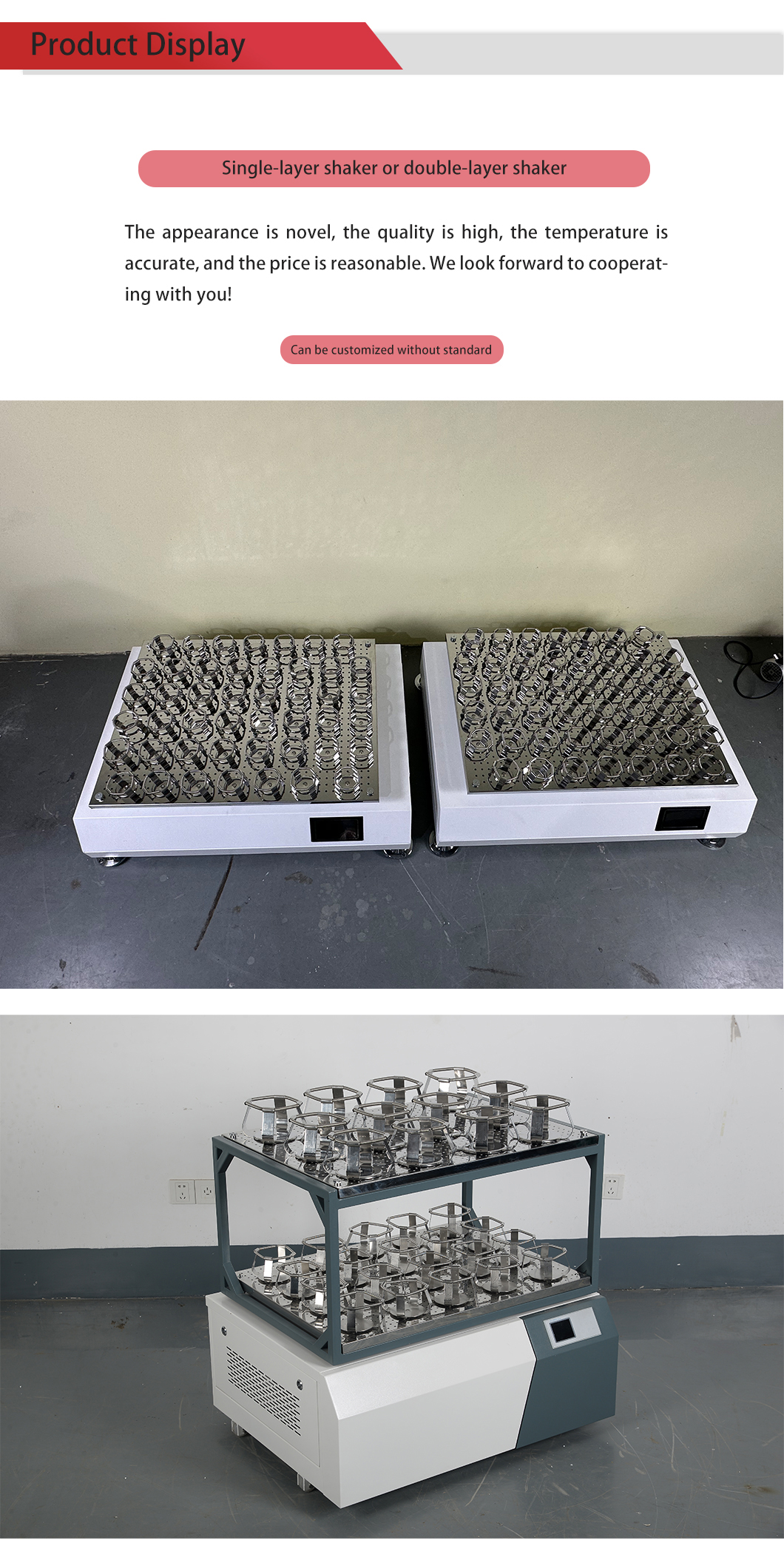

Small Portable Single-Layer Bottle Shaker Hospital Incubator

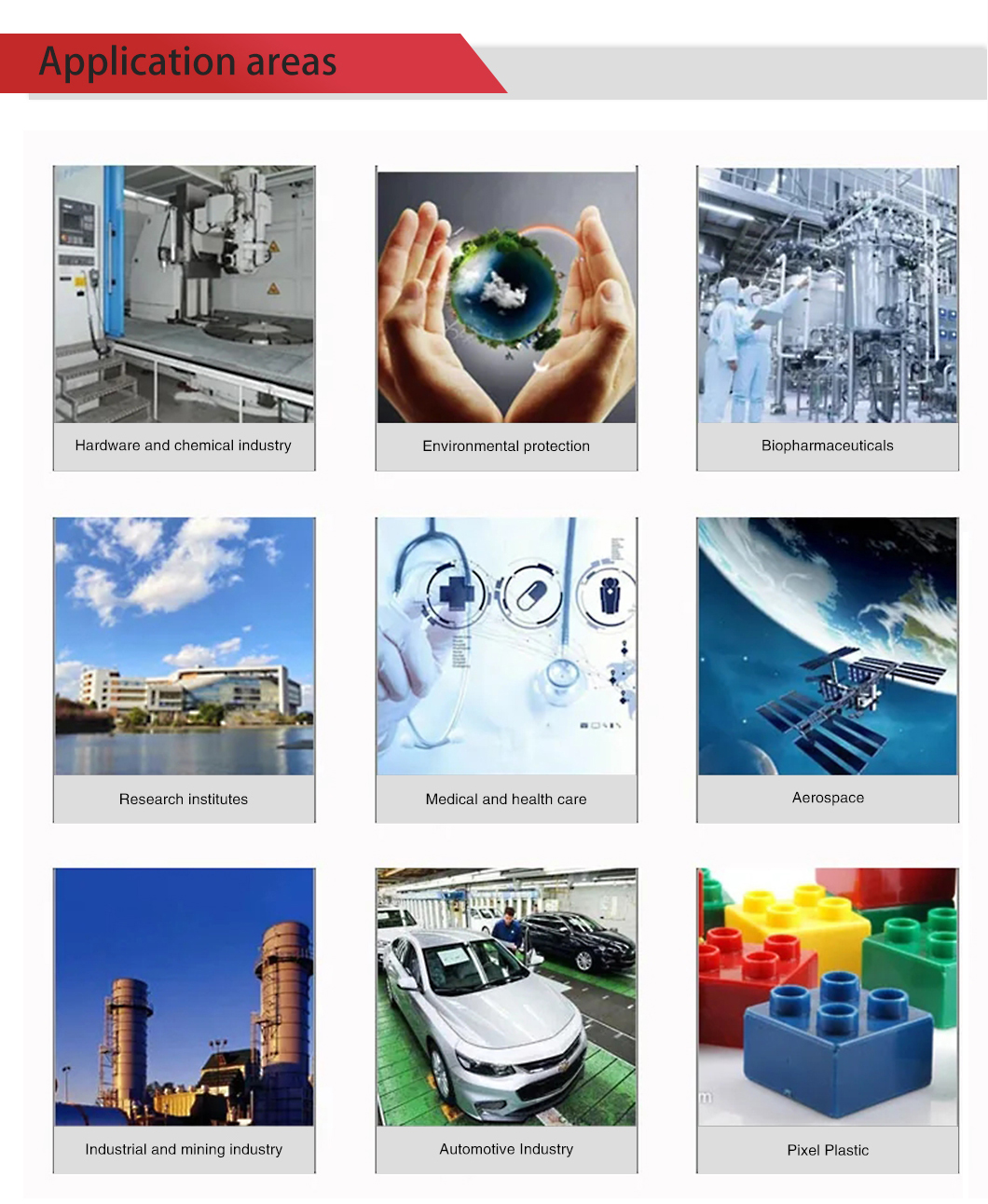

Shaking bottle machine products are widely used in the pharmaceutical industry for bacterial culture, fermentation, hybridization and biochemical reactions, as well as enzyme and cell tissue research. It has a wide and important application in medical, biological, molecular, pharmaceutical, food, environmental protection and other research and application fields. Shaking bottle machine is an open oscillation equipment. This equipment is suitable for centralized constant temperature and cluster oscillation in the same constant temperature room for mass production operations. This model has a simple structure, It has strong economy and practicability.

Product Details

Double or triple rocker bottles

■ scope of application

Shaking bottle machine products are widely used in the pharmaceutical industry for bacterial culture, fermentation, hybridization and biochemical reactions, as well as enzyme and cell tissue research. It has a wide and important application in medical, biological, molecular, pharmaceutical, food, environmental protection and other research and application fields.

Shaking bottle machine is an open oscillation equipment. This equipment is suitable for centralized constant temperature and cluster oscillation in the same constant temperature room for mass production operations. This model has a simple structure,

It has strong economy and practicability.

■ Product features

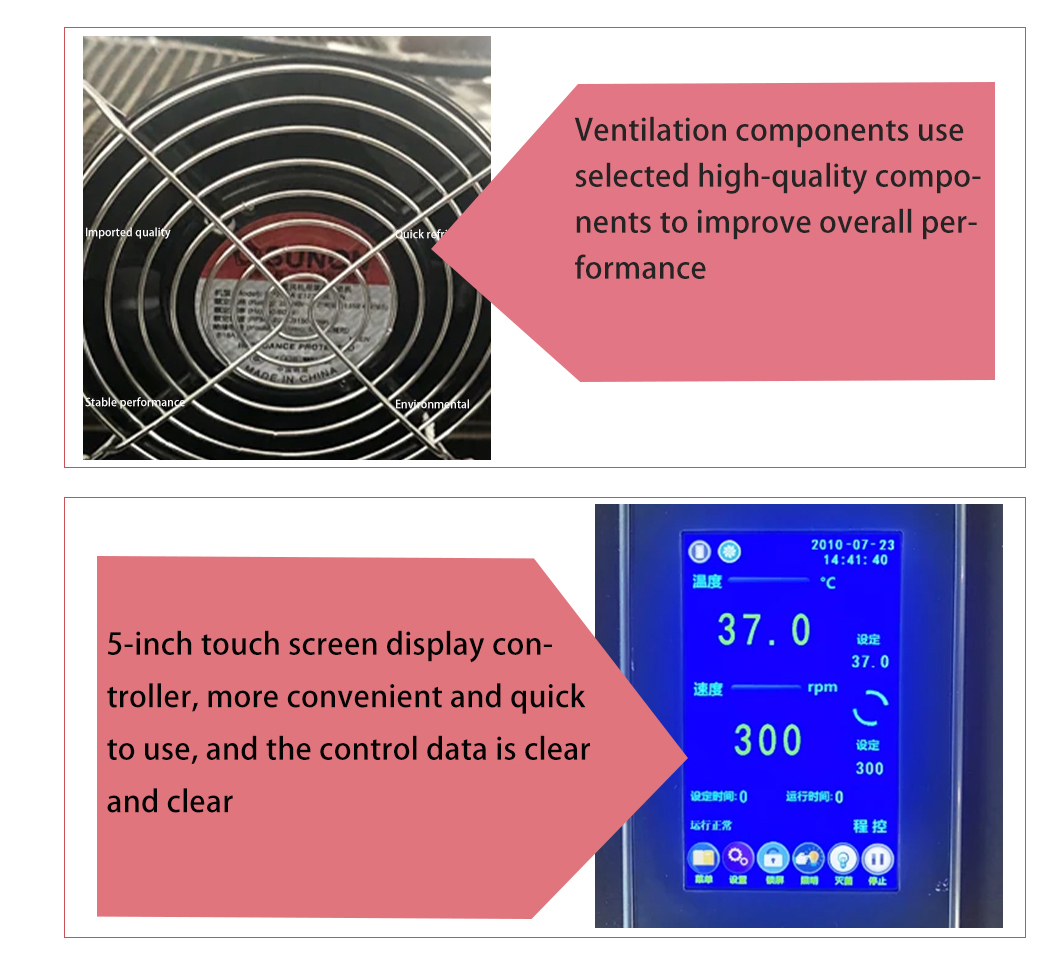

1. Intelligent sound and light alarm environment scanning microprocessor controller

2. LCD large screen backlight LCD display shows the set parameters and measured parameters

3. Encrypted and locked operation parameters to avoid human error and memory function of operation parameters

4. The timing setting is up to 500 hours, and the oscillation will stop automatically at the end with sound and light alarm

5. Exchange induction long life motor design, wide speed control, constant torque, constant speed, no carbon brush, maintenance free

6. The control line of acceleration ensures that the shaking bed starts slowly and accelerates smoothly, ensuring the safety of the experimental samples

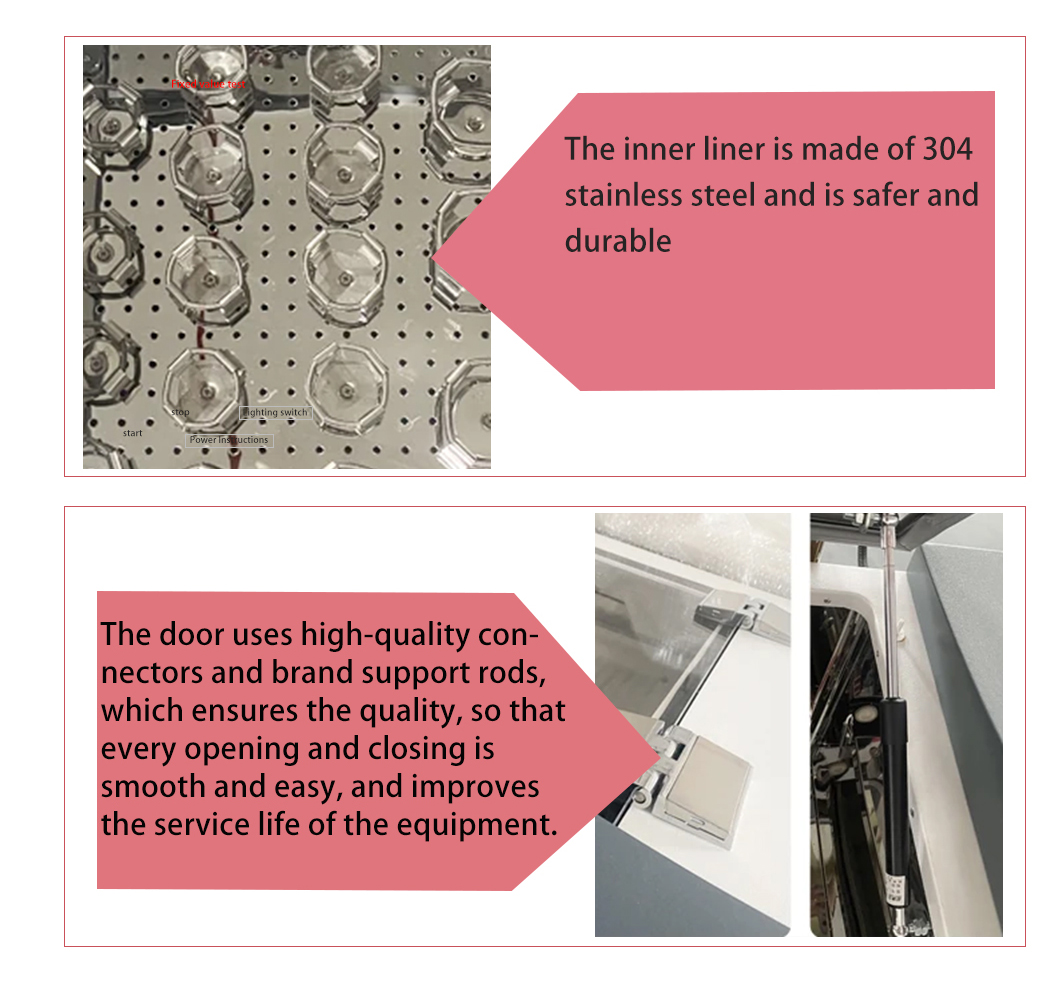

7. The key parts are made of high quality cast iron and aluminum, which is strong and durable

8. The streamlined luxury machine with aesthetic design concept, electrostatic spraying box, large screen LCD display, stable operation

■ technical parameter

|

product name |

Double layer shaking flask machine |

Single-layer shaking tank |

Double layer shaking flask machine |

Single-layer shaking tank |

3 tier shake flask machine |

||

|

product model |

TS-3112 |

TS-311 |

TS-3222 |

TS-322 |

TS-3333 |

||

|

gyro-frequency |

30-300rpm |

60-2800rpm |

|||||

|

running accuracy |

±1rpm |

||||||

|

The way of shaking |

Rotary |

||||||

|

operating ambient temperature |

5℃~40℃ |

||||||

|

display mode |

LCD screen display |

||||||

|

Time range |

0~999 hours |

||||||

|

Swing amplitude |

Φ35mm/Φ50mm |

||||||

|

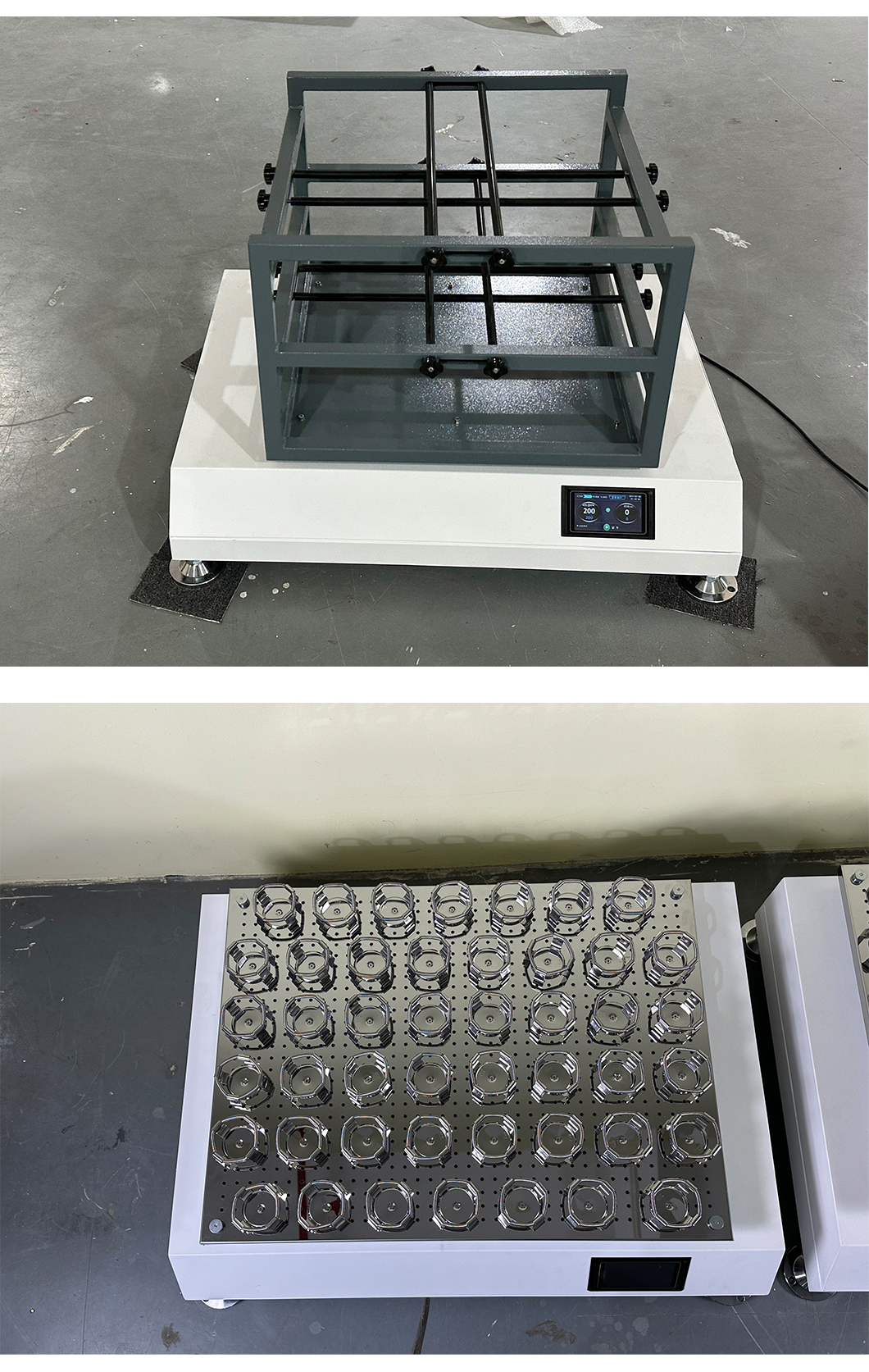

Pallet size |

800*600mm |

800*600mm |

900*640mm |

800*600mm |

325*520mm |

||

|

standard layout |

500ml x 60 |

500ml x 30 |

1L x 44 pieces |

1L x 22 pieces |

500ml x 288 |

||

|

max. cap |

250ml x 46 vials or 500ml x 30 vials or 1L x 20 vials or 2L x 12 vials (per level) |

250ml x 60 or 500ml x 35 or 1L x 22 or 2L x 16 (per layer) |

500ml x 288 pieces |

||||

|

Number of pallets |

2 block |

1 block |

2 block |

1 block |

12 block |

||

|

Size W.D.H |

900*680*680 |

900*680*680mm |

1060*850*680 |

900*680*680mm |

1450*1100*1500 |

||

|

net weight |

290KG |

260KG |

360KG |

330KG |

650KG |

||

|

power |

400W |

1100W |

|||||

|

source |

AC220V~240V 50HZ~60HZ |

||||||

|

display mode |

A screen of liquid crystals displays |

||||||

|

apolegamy |

Printer, RS485 interface, mobile phone remote control and other ancillary functions are optional |

||||||